By compacting recyclable supplies into bales, balers enable conserve landfill Room and lessen the associated environmental impacts. Recycling also saves Vitality, reduces greenhouse gasoline emissions, and conserves all-natural assets.

A higher-ability baler with a substantial feed opening to simply accomodate cumbersome bins and expandable plastics.

Horizontal balers compress supplies horizontally, enabling ongoing feeding and generating dense bales.

The HSM V-Press 610 cuts down the amount of cardboard, mixed paper or plastic movie. With minimum set up peak and footprint, this vertical cardboard bailer gives comfort and House performance. Door style: Double door

The shredder is placed under the chute and several other bales are dropped in. A employee then pushes the shredder alongside the barn aisle as it rips up a bale and spews it out in a ongoing fluffy stream of material.

Bale Ejection Process: After compacted to the desired density, the baler ejects the concluded bale in the compression chamber, Completely ready for storage or transportation.

During the early eighties, collaboration concerning Walterscheid and Vermeer developed the very first helpful employs of CV joints in balers, and later in other farm equipment.

The chance to deliver leading good quality bales in all crop ailments sets KUHN significant square balers other than Some others. Flawlessly shaped bales, coupled with significant output and outstanding durability, ensure the KUHN square baler will likely be a rewarding financial investment.

Compression: As soon as the products are In the baler’s chamber, a robust hydraulic ram activates and creates stress within the resources.

Given that the stack crammed the loft, the bales will be lifted higher and better With all the pulleys until the hay was stacked the many way nearly the height.

In addition it minimizes the amount of collections you require, cutting website targeted visitors, nearby environmental affect and Total CO2 emissions.

At 56000 lbs of crushing pressure, the BACE V43DC can crush a metal drum down to a height of 4-six inches tall. Simple here pushbutton operation and automatic cycling would make this equipment ideal for a armed forces set up, a pharmaceutical processor or perhaps a production plant and recyclers.

Our plastic and cardboard balers are specially made for productive compaction of recyclable waste, which include OCC, tender plastic, aluminum cans with residual liquids, and bags. The higher-compaction ratio here equals compact and dense bales which might be uncomplicated to maneuver and retail store.

This back links all linked compaction devices with IT units, balers providing you with a 360 diploma view of your equipment reducing immediate and oblique waste dealing with charges after a while.

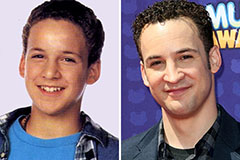

Ben Savage Then & Now!

Ben Savage Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!